|

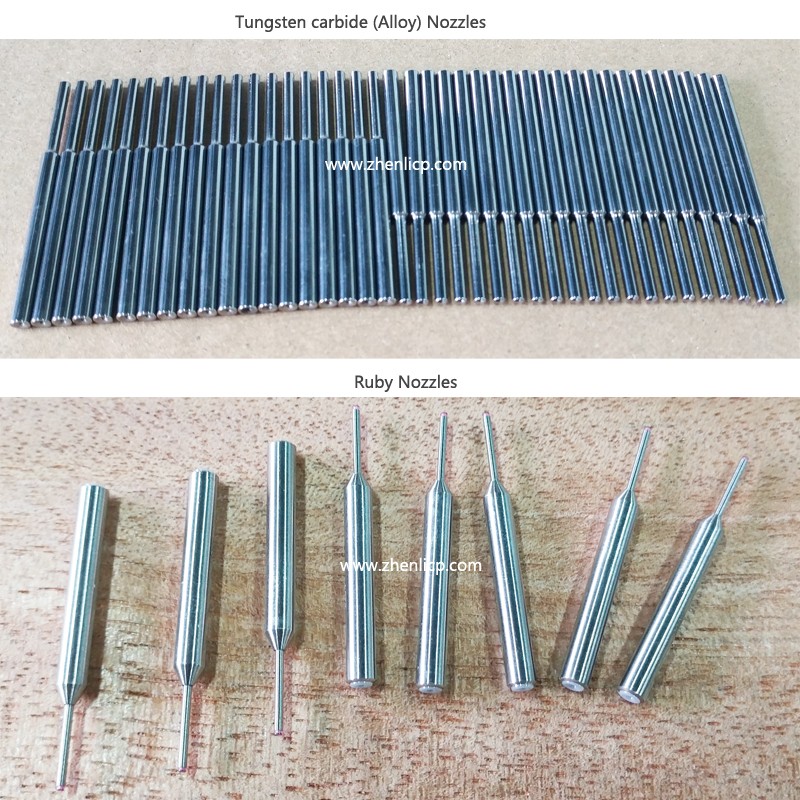

How to choice suitable winding machine nozzle guideTime:2017-10-08 The key to choosing a wire winding machine nozzle guide pin is not how good the exterior finish is, the exterior finish is not relevant to the quality of the product being winding, it is just beautiful, the inner good is what is worth noting. Here are somes points shared by Zhenli Technology Limited for your reference. *, the accuracy of the installation size. The consistency of the installation size is necessary, if it is large it is difficult to fit into the equipment tool, if it is small it is easy to fall out of the tool and affect the adjustment accuracy. Second, the size of the inner hole accuracy. Precision machining and manufacturing of wire nozzle, it can control the accuracy of the inner hole within 0.01mm, if the size of the inner hole is large or small, it is a disaster for the user, the phenomenon of broken wires will often occur, and even the winding coil defective insulation or coil winding is not neat, affecting the beauty of the coil. Third, the head and tail of the R shape. The R shape of the head and tail is also a key part of the winding nozzle, R too large or too small are affecting the quality of the product and can with stand the tension. Fourth, the inner hole finish. It is also very critical to the quality of the product, in the process of product winding, enameled wire in the inner hole of the winding nozzle is in a state of jumping, if the inner hole grinding treatment is not good, then scraping the line is inevitable. It is worth reminding that there are many alloy wire nozzles on the market today, the inner hole is not processed by precision grinding or simple rough processing. Fifth, the line mouth orifice finish. It's location at the junction of the inner hole and the arc angle, with visual methods can not be seen, only with the help of high magnification to observe the side view, if the junction of the inner hole and the arc angle there is an obvious junction marks, then it is the result of scratching the enameled wire, if it is a good quality wire nozzle, its inner hole and the junction of the arc angle is a natural excess, no junction marks. Any dimension can be customized.welcome to contact us to talk more. Tungsten Carbide Coil Winding NozzleNeedle Spray Nozzle Machine Spring Abrasive Machine Carbide Drill Carbide Bit Winding Nozzle Needle Spray Nozzle Coil Winding Nozzle Bend Nozzle |

ICP:2022111349-1

ICP:2022111349-1