|

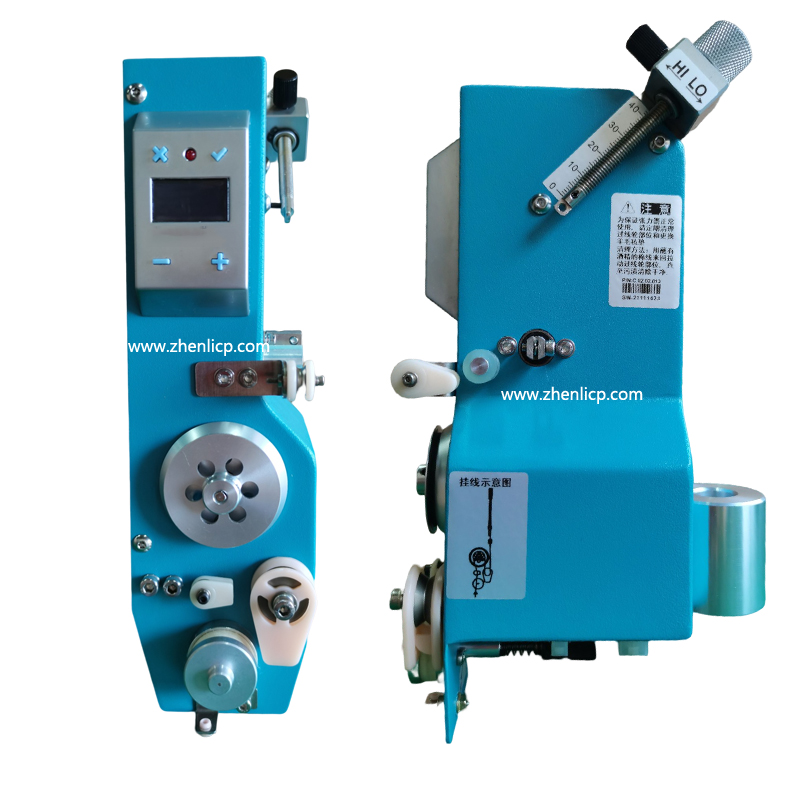

How to maintain ETA electronic tensionerTime:2020-08-01 1:Product Description Features of ETA Series Electronic Tensioners: 1. The tension is controlled by excitation current with accuracy +/-2% in Auto mode.It provides stable tension under high speed wiring and closed-loop tension control is possible. 2. Different types of tension setting: The output tension can be altered rapidly (output tension is reference to the setting value) by switching the signal input so that intelligent control isachieved. 3. Remote control and data collection through the RS485 communication port to monitor 2:Maintance 1. Periodically clean the tensioner, wool-felt clip, tension wheel, ceramic eyelet, wire rollers according to the usage situation. Replace the wool-felt if necessary to ensure the tensioner work properly. 3:Cautions 1. Do not touch or try to stop the tension arms and the wiring wheels or rolls. 2. Do not directly touch the tension sensor wheel with hands to avoid the damage of sensor which will affect the accuracy of tension value measured. 3. Install the tensioner properly to prevent the falling of tensioner. 4.Adjust the pressure applied by the wool-felt clip (avoid too high) and the force by spring to ensure the tension wheel is running properly. 5. Turn the tension wheel to eliminate the magnetism pulse when changing the current from large to small or it will affect the wiring performance. 6. Ensure the enameled wires go through the wire jump preventer and the wire wheels properly but not hanged over the contact roller so that the wheels rotate smoothly. 7.Keep away from oil contamination to the tension pulley, or it will affect the tensioner running well. Use the cotton thread with absolute alcohol to clean it by pulling back and forth of the “O” shape part, if the oil contamination exists. 8.Wool-felt clips, ceramic eyelet, wire roller and the tension arm are consumable parts. Charging s is required for replacement even the tensioner is within the warranty period. Please contact our factory for the cost. 9.Over limit application or improper model using is prohibited. Repair or components disassembly can only be done in factory. 10. Clean the parts where wires passing through, especially for the waxed enameled wires are used. Periodically replace the wool-felt clips to keep the tension constant and avoid slipping. Otherwise, it will shorten the life of tensioner. 4:Common faults Failures 1: Enameled wires got stuck in the tension wheel to cause the rotation stop. Solution: Unscrew the fixing screw to take out the tension wheel and clean the impurities inside. Failure 2: Wire get stuck with tension arm or wire roller or not running Solution: 1. Too thin wires may get stuck outside the wire roller. Please examine carefully and wire again; 2. Replace the wire roller if it is caused by the ageing of wire roller after long time usage. Failure 3: Tension pulley slips while operating Solution: 1. Change the wool felt if it is caused by oil or impurities on it. 2. Use the cotton thread with absolute alcohol, and then pull back and forth to clean the tension pulley Failure 4: Tension pulsating exists Solution: To enter the demagnetization mode. Turn the tension wheel during the demagnetization or it will be invalid. Coil Winding Wire Tensioner Magnetic Tensioner Winding Machine Magnetic Wire Coil Winding Tensioner |

ICP:2022111349-1

ICP:2022111349-1